-

Home

-

Products

-

Welding Table

- Octagonal Welding Table

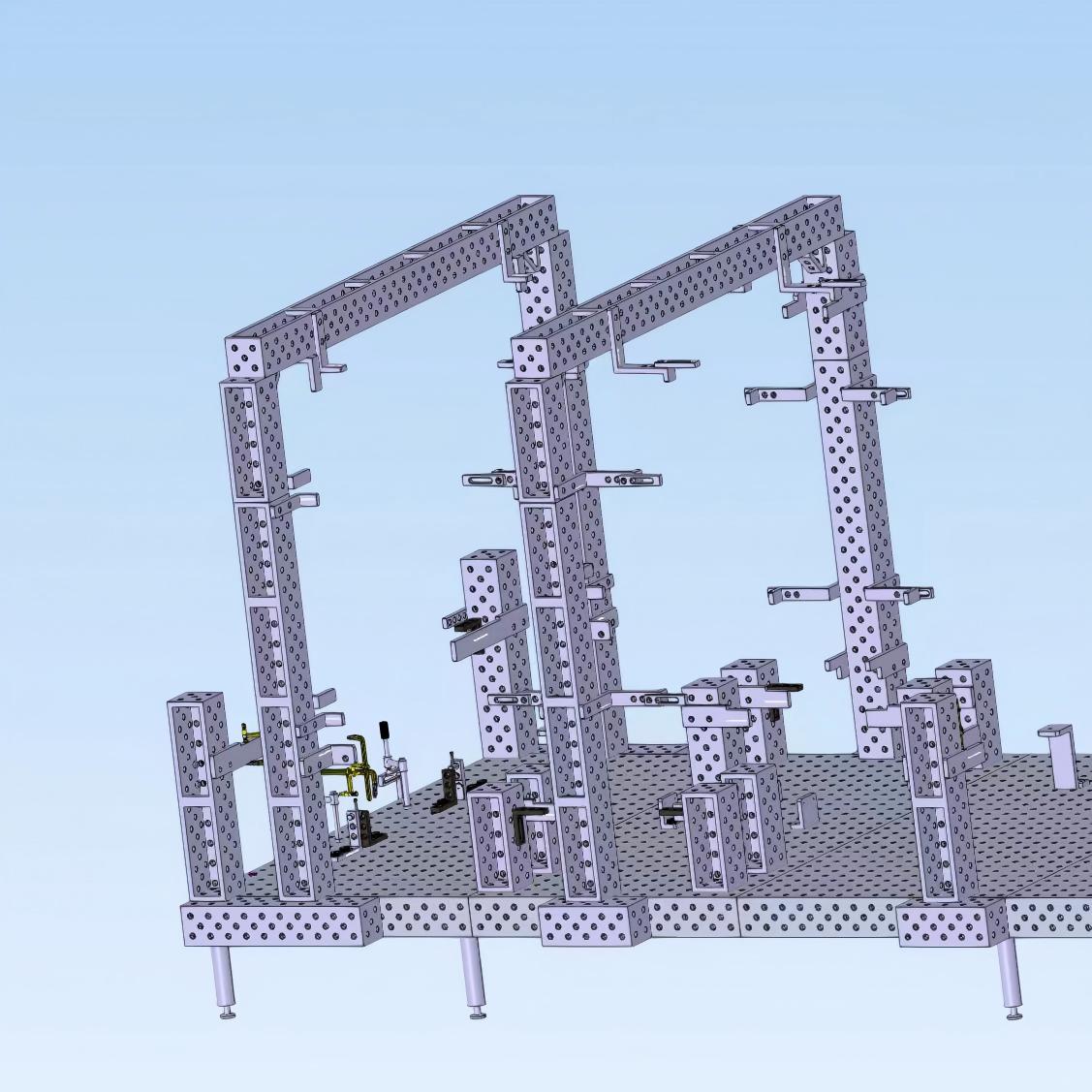

Octagonal Welding Table

- Modularity and flexibility

- High precision

- Quick fixing and clamping

- Easy to operate

- High price-performance ratio

- Clean, tidy and environmental Friendly

Welding table features

1.Modularity and flexibility

Can be connected and changed arbitrarily according to the shape of workpiece.

2.High precision.

The precision can reach decimillimetre(dmm) for fixing and clamping.

3.Quick fixing and clamping.

Only spending a few minutes to fix and clamp workpieces from one to another.

4.Easy to operate.

Only 2 hours, any worker can learn how to use it quickly.

5.High price-performance ratio.

1 set of modular flexible fixture can replace all traditional dedicated fixtures. Saved a lot of time, labor, material resources and funds for enterprises.

6.Clean, tidy and environmental Friendly.

Compared with mountains of rusty dedicated fixtures, modular flexible fixtures are the optimal choice.

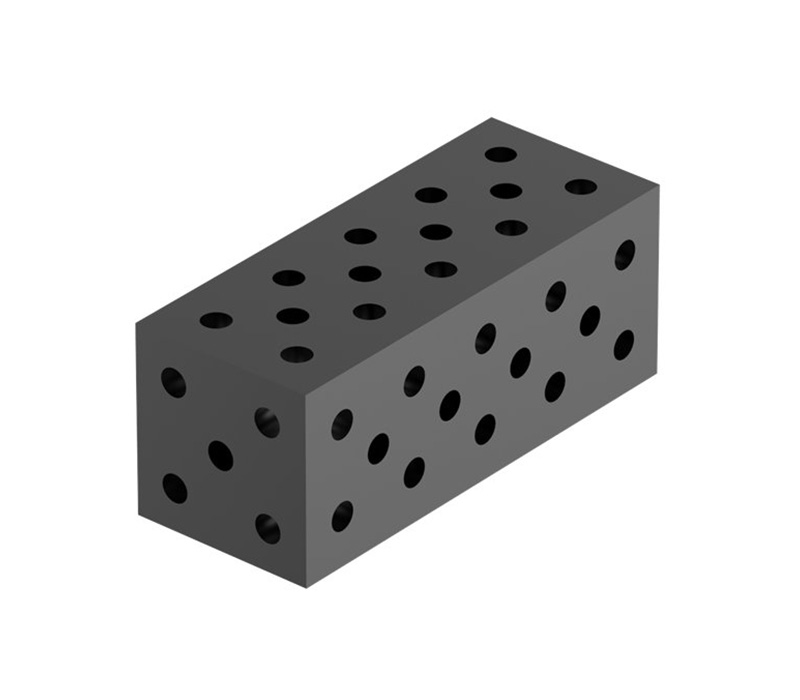

D28 Octagonal Platform

| L(mm) | W(mm) | H(mm) | Type No. | Surface Treatment |

| 800 | 800 | 200 | D28FDT-OT01 | Polished/Nitrided |

| 1000 | 1000 | 200 | D28FDT-OT02 | Polished/Nitrided |

| 1200 | 1200 | 200 | D28FDT-OT03 | Polished/Nitrided |

| 1400 | 1400 | 200 | D28FDT-OT04 | Polished/Nitrided |

| Other specifications or materials can be customized | ||||

Product Parameters

D28 Parameters

Material: S355JR(Q355B)

Aperture: φ28.065 — φ28.149mm.

Hole spacing: L1=100±0.05mm

Flatness: 0.1/1000mm.

Bearing: More Than 500kgs.

Hardness: Hardness of nitriding layer: HV450-HV630

D16 Parameters

Material: S355JR(Q355B)

Aperture: φ16.065 — φ16.149mm.

Hole spacing: L1=50±0.05mm

Flatness: 0.1/1000mm.

Bearing: More Than 500kgs.

Hardness: Hardness of nitriding layer: HV450-HV630

OUR PRODUCTS

Best-selling Products

OUR LATEST

Our Latest Blog & News

SERVICES

Services

After-Sales & Logistics Support

Training & Technical Support

Technical & Customization Services