-

Home

- Products

Our Prodcuts

The fundamental advantage of this system is its modularity and flexibility. Unlike traditional, single-purpose fixtures, this table uses a standardized grid of holes (D16 series with 50mm spacing for smaller parts; D28 series with 100mm spacing for larger structures) to allow infinite configurations . This "one system fits all" approach is profoundly economical. It eliminates the need and cost for storing, designing, and manufacturing dedicated fixtures for every new product or design change. The table can be easily expanded with U-shaped/L-shaped boxes and support angles, making it a long-term, reusable asset that drastically reduces preparation time and overall tooling investment

Precision Engineering and Operational Reliability

Engineered for precision and reliability, our welding tables are built from high-quality steel, precision-machined, and treated with nitriding and heat processes for superior rust and wear resistance. The high-tolerance hole system maintains positioning accuracy within ±0.05mm, while robust construction ensures minimal deformation under heavy loads (e.g., up to 2 tons), also making the table suitable as a reference base for inspection tools.

User-Centric Operation and Long-Term Value

The welding table is designed for practical shop-floor use, emphasizing ease of operation and efficiency. Its "building blocks" concept is intuitive, allowing any worker to learn basic setup quickly. The tool-less or quick-clamp system enables fixture reconfiguration in minutes instead of hours, significantly accelerating production changeovers and time-to-market for new products . This leads to a clean, organized, and safe working environment, free from piles of rusty, dedicated fixtures. The initial investment is quickly offset by the savings in labor, materials, and storage space, providing a high price-to-performance ratio and a strong long-term ROI.

The selection of welding tables should be based on the size and shape of the product, and D16 series platforms are commonly used for sheet metal and small steel structural components;

The D28 series platform is commonly used in the large steel structure and heavy machinery industries.

The selection of accessories should be based on the shape, size, and complexity of the workpiece. When the table cannot meet the size of the workpiece, U-shaped square boxes, L-shaped square boxes, supporting angle irons and other supporting components can be used for expansion and extension.

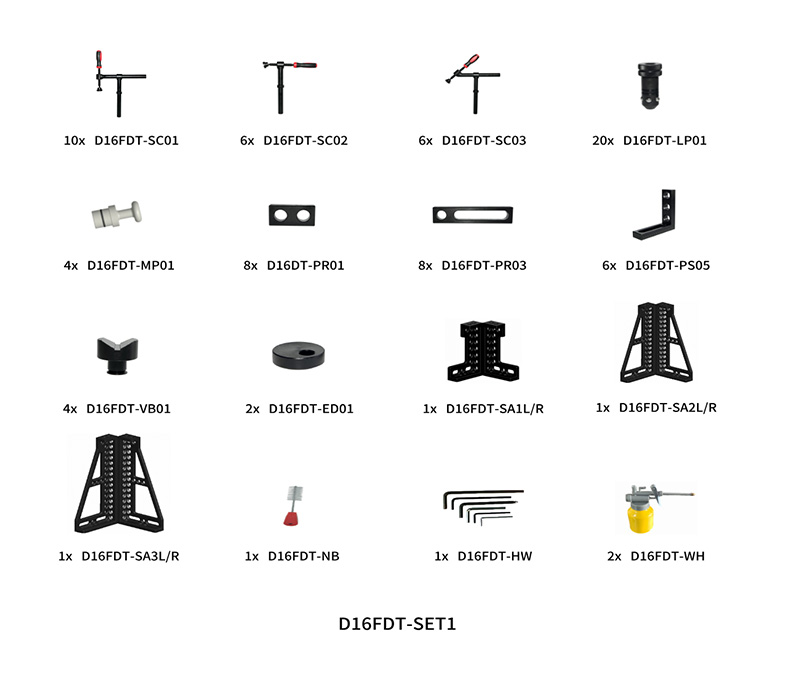

The Welding Fixture offers a comprehensive range of modular clamping and positioning tools designed to work seamlessly with our welding tables. This includes a variety of clamps, stops, pins, and angle pieces that securely attach to the table's grid. The key advantage of our fixtures is their modularity and reconfigurability; they can be quickly adjusted or completely rearranged to accommodate different workpiece geometries without the need for custom, dedicated jigs. This flexibility is crucial for reducing lead times and costs associated with traditional tooling. From simple manual clamps to complex pneumatic setups, these fixtures ensure precise and repeatable positioning of parts, which is essential for maintaining weld consistency and quality in industries like automotive and aerospace.

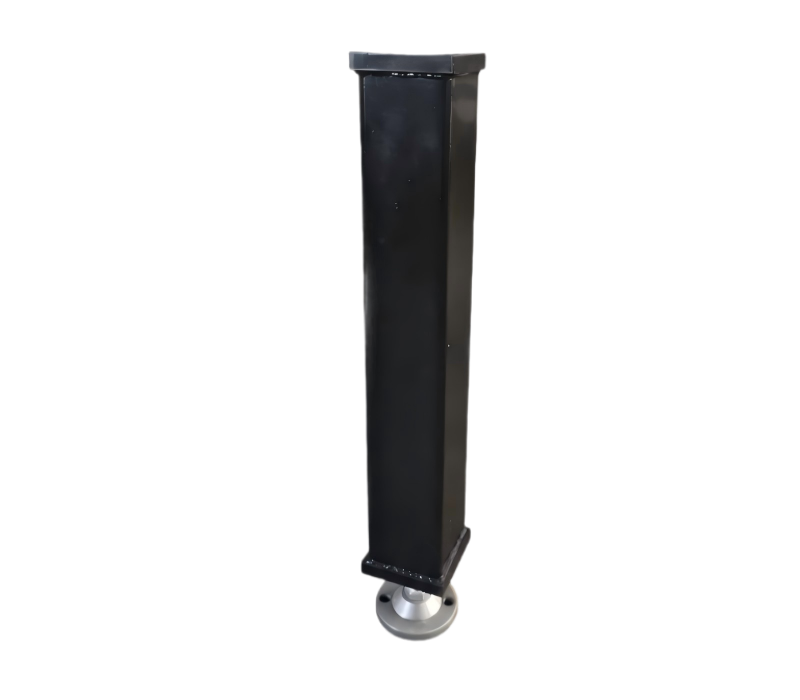

Standard Legs: Designed for reliable, general-purpose use in everyday workshop environments.

Heavy-Duty Legs: Constructed with robust materials to provide enhanced stability and maximum load capacity for heavy industrial applications.

Universal wheel Legs: Equipped with wheels (casters) that include a locking mechanism, offering easy mobility around the workshop and secure stabilization in place when needed.

Adjustable Legs: Enable a continuous and wide range of height adjustments (e.g., from 500mm to 800cm), making them ideal for achieving the optimal, ergonomic working position for various tasks and operators.

FREQUENTLY ASKED QUESTIONS

Have Any Questions

-

Can the size and logo be customized?

In addition to the regular size, different sizes and thicknesses can be customized according to the actual processing needs of the customer.

-

Can technical advice and consultation be provided?

Of course, we provide you with professional technical advice and usage guidance

-

Does it meet the export packaging requirements?

We use plywood wooden boxes to ensure thatmeet export requirements, and, in order to minimize transportation costs, before shipment, the packaging size of the product is carefully calculated. No packaging space is wasted.

-

Is there a professional export department?

We have professional export personnel with more than 15 years of experience, providing full-service from quotation, ordering, shipping, and receipt. We ensure that every link of your import can be completed in a timely and smooth manner.

-

How do we ensure quality?

Pre-production samples are always provided before mass production; final inspection is always performed before shipment.

-

How is your quality control?

Our quality control steps include:

(1) Confirm everything with the customer before purchasing and production;

(2) Check all materials to ensure they are correct;

(3) Hire experienced workers and train them properly;

(4) Perform inspections throughout the production process;

(5) Strict quality control before shipment