Welding Table

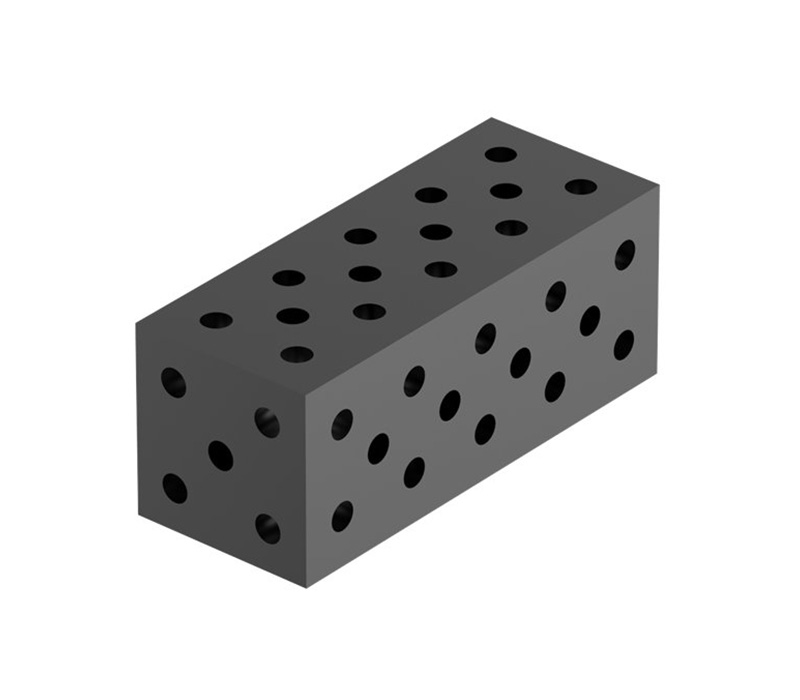

D28 3D WeldingTable

D28 2D Welding Table

D16 3D Welding Table

D16 2D Welding Table

Octagonal Welding Table

U Shape Box And L Shape Box

FREQUENTLY ASKED QUESTIONS

Have Any Questions

-

Can the size and logo be customized?

In addition to the regular size, different sizes and thicknesses can be customized according to the actual processing needs of the customer.

-

Can technical advice and consultation be provided?

Of course, we provide you with professional technical advice and usage guidance

-

Does it meet the export packaging requirements?

We use plywood wooden boxes to ensure thatmeet export requirements, and, in order to minimize transportation costs, before shipment, the packaging size of the product is carefully calculated. No packaging space is wasted.

-

Is there a professional export department?

We have professional export personnel with more than 15 years of experience, providing full-service from quotation, ordering, shipping, and receipt. We ensure that every link of your import can be completed in a timely and smooth manner.

-

How do we ensure quality?

Pre-production samples are always provided before mass production; final inspection is always performed before shipment.

-

How is your quality control?

Our quality control steps include:

(1) Confirm everything with the customer before purchasing and production;

(2) Check all materials to ensure they are correct;

(3) Hire experienced workers and train them properly;

(4) Perform inspections throughout the production process;

(5) Strict quality control before shipment