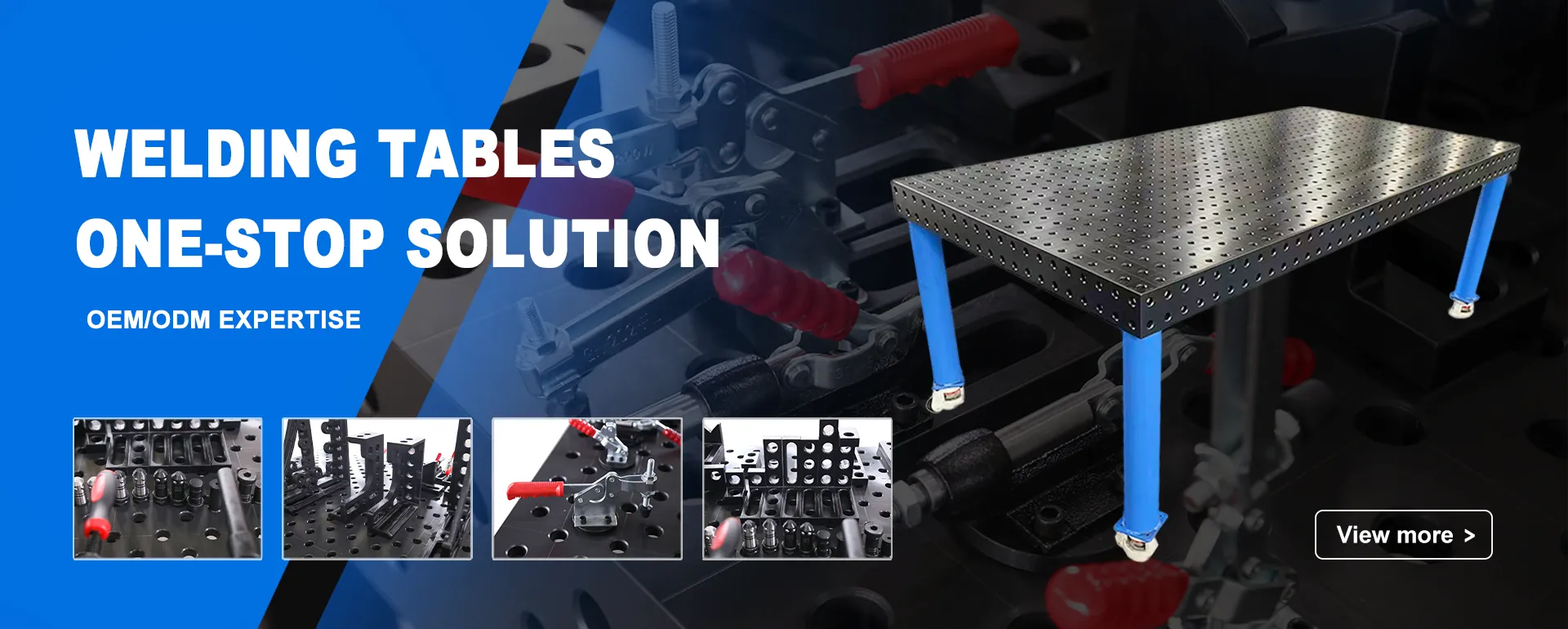

OUR PRODUCTS

Best-selling products

our service

service

Quality Warranty: Reliable product warranties and after-sales support, with some offering a 12-month warranty . Precision Maintenance: Services for checking and recalibrating table precision over time . Spare Parts Supply: Guaranteed availability of replacement parts and accessories . Export Expertise: Experience in international shipping, handling terms like FOB, CIF, and CFR, with Tianjin Port as a primary export hub

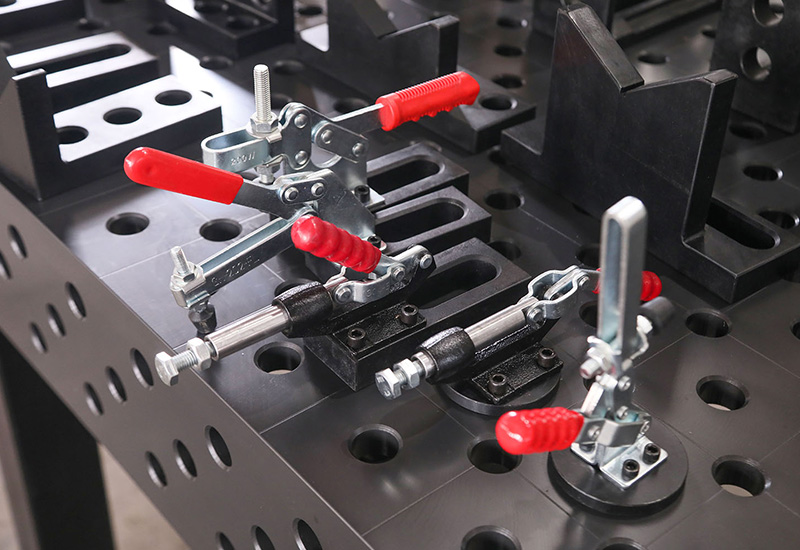

Installation & Calibration Guidance: On-site or remote support for platform setup and precision leveling . Operational Training: Comprehensive training for your team on how to efficiently use and reconfigure the modular system . Technical Consultation: Ongoing support to solve welding challenges and optimize your tooling strategies.

Custom Fixture Design: Expert design of welding fixtures tailored to your specific workpiece, leveraging CAD technology . Custom Table Manufacturing: Production of platforms to your required dimensions, materials (cast iron or steel), and specifications . Automation Integration Solutions: Designing and providing solutions to integrate our platforms with robotic welding cells for automated production lines.

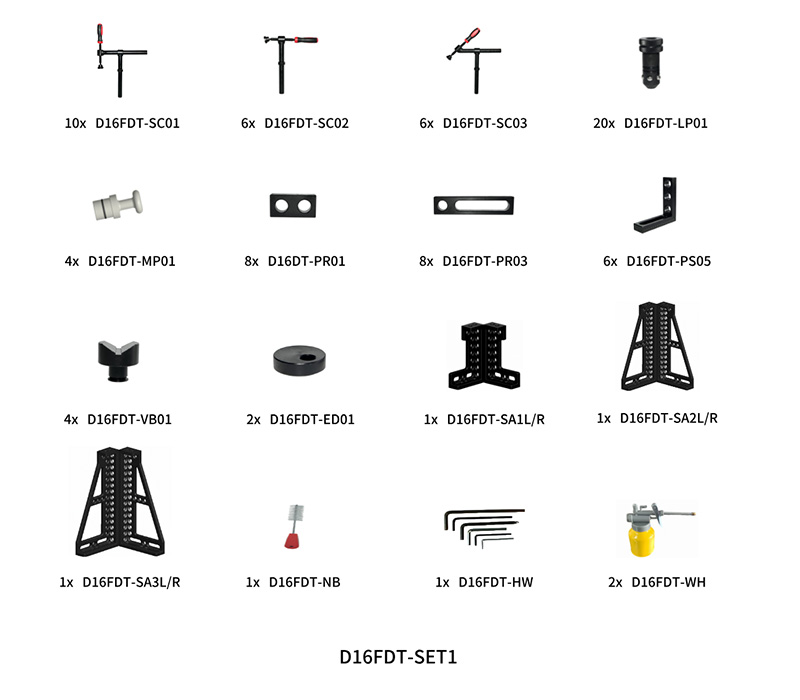

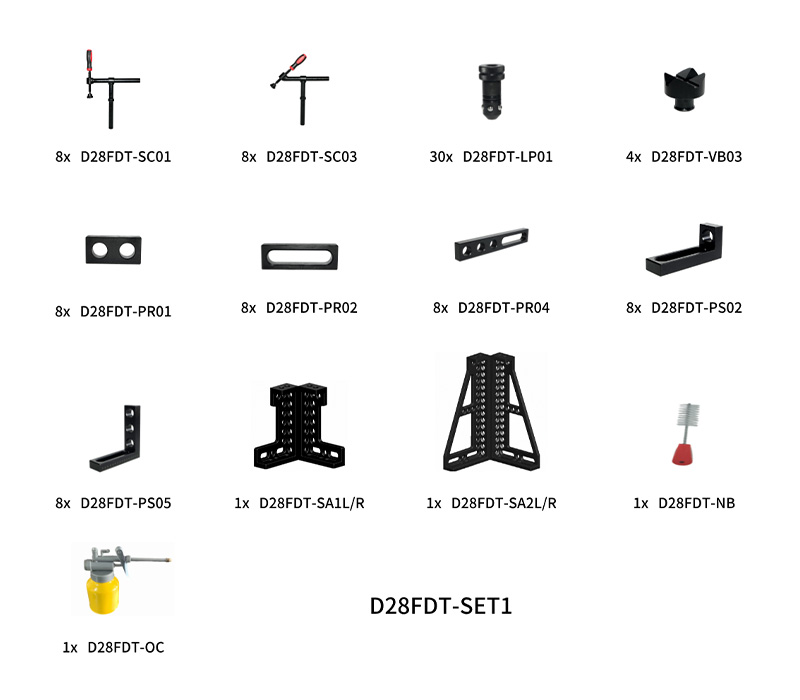

Supply of standard and custom-sized 3D flexible welding tables (e.g., 4000x2000mm and larger), available in D28 (Φ28mm) and D16 (Φ16mm) hole series with precise hole spacing . Provision of a full range of high-precision, modular clamping accessories (e.g., square boxes, angle irons, locating pins, clamping components) to build any fixture

ABOUT COMPANY

Why Choose Us

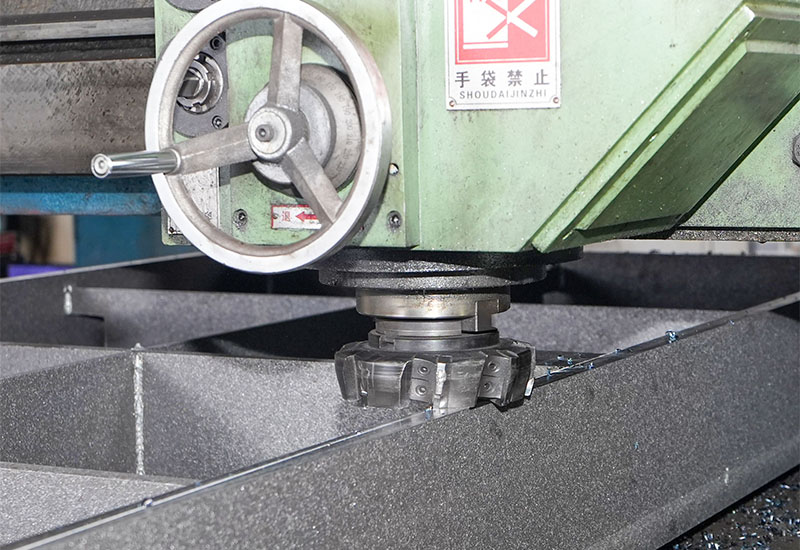

Superior Quality:Our welding tables are constructed from high-quality steel, undergo specialized surface treatments including nitriding and heat treatment. This process ensures exceptional rust-proof and wear-resistant properties.

Broader Capabilities:Beyond our flagship welding systems, our extensive business scope covers general and specialized equipment manufacturing, environmental protection equipment, and large-scale casting and machining services. We also provide comprehensive OEM/ODM project support.

Technical Proficiency:We leverage CAD technology in our product design and development processes, ensuring precision and enabling customization to meet specific client requirements.

Global Reach:We are experienced in international trade. Our products have successfully reached key markets including Oceania, Europe, and America, with export business constituting a significant portion of our operations.

Broader Capabilities:Beyond our flagship welding systems, our extensive business scope covers general and specialized equipment manufacturing, environmental protection equipment, and large-scale casting and machining services. We also provide comprehensive OEM/ODM project support.

Technical Proficiency:We leverage CAD technology in our product design and development processes, ensuring precision and enabling customization to meet specific client requirements.

Global Reach:We are experienced in international trade. Our products have successfully reached key markets including Oceania, Europe, and America, with export business constituting a significant portion of our operations.

00

years+Industry Experience

00

m²+Production Facility Area

00

+Advanced production line

00

+Export Market Reach